Team uses RCAC clusters for groundbreaking catalyst design research by simulating the largest systems ever

A team led by Purdue researchers has used the Rosen Center for Advanced Computing (RCAC)’s community clusters for a groundbreaking catalyst research and design paper recently published in Nature.

Jeffrey Greeley, the Charles and Nancy Davidson Professor of Chemical Engineering, and Zhenhua Zeng, a research scientist at Purdue, worked with researchers at Hunan University in China, Leiden University in the Netherlands and Clarkson University, to demonstrate the existence of a fundamentally new class of “active sites,” spots on the surface of a catalyst where molecules bind and undergo a chemical reaction. The findings not only offer valuable perspectives on prior studies in catalytically active sites, but also forecast the development of new catalysts with notably enhanced performance for hydrogen fuel cells and other electrochemical devices.

The use of heterogeneous catalysts in chemical reactions is widespread, with the understanding that high catalytic activity occurs only on specific surface sites, known as active sites. Determining the atomic structure of active sites is a central and longstanding goal of catalysis science.

Until the Nature paper led by Greeley and Zeng, these active sites were identified and classified through distinct surface motifs such as steps and terraces. This categorization often oversimplifies the complexity of active site identification, which can in turn lead to uncertain classification of active sites and incorrect predictions of catalytic activity, which hinders catalyst design.

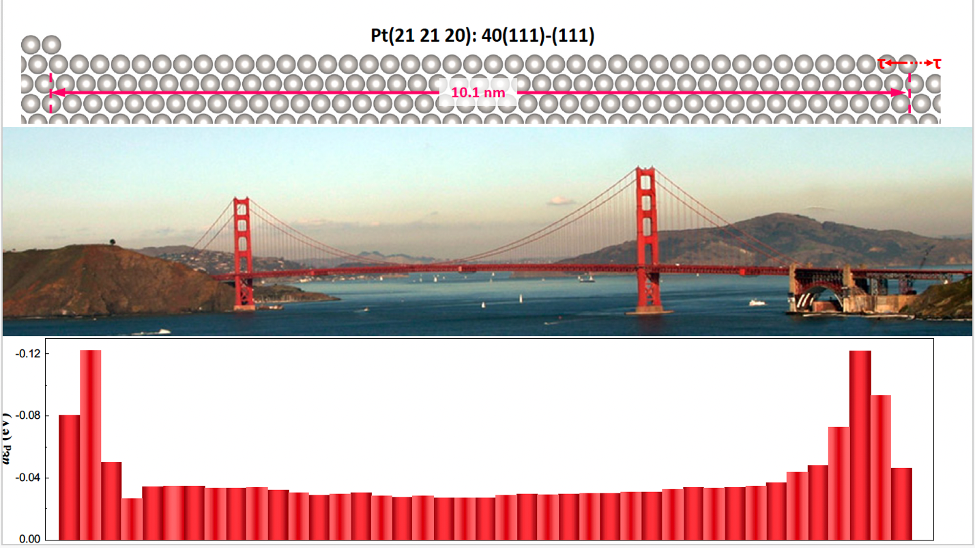

Using stepped Pt(111) [platinum] surfaces and the oxygen reduction reaction (ORR) in fuel cells as examples, the paper demonstrates that surface stress release produces inhomogeneous strain fields, leading to distinct electronic structures and reactivity for terrace atoms with identical local coordination. Furthermore, the terrace atoms surrounding the steps can experience up to 50 times enhancement higher than the atoms in the center of the terrace causing some areas of the terrace to experience higher or lower ORR activity.

The researchers concluded that the ability to control ORR reactivity through altering terrace widths or regulating external stress opens new doors for catalyst design.

This work represents a paradigm shift in the field of catalyst design by revealing a solution for the oversimplified categorization: atomic site-specific reactivity driven by surface stress release, which was often overlooked in the previous classification process.

“Our work challenges the conventional assumption of uniform reactivity among atomic sites with identical local environments, revealing distinct reactivity induced by even minor imperfections,” says Zeng. “This paper provides atomic-scale insights into active sites of stepped Pt surfaces, particularly focusing on their role in hydrogen fuel cells. This fundamental understanding not only provides compelling insights into previous experiments but also predicts new catalysts with significantly improved performance.”

The research team used RCAC’s powerful Brown and Bell clusters for this work, and in the process simulated the largest systems ever published in this field. The calculations require an enormous amount of computational power, to the point that they wouldn’t have been possible a decade ago even on a powerful supercomputer.

The design of clusters like Bell was crucial to accomplish the computational work efficiently.

“The new generation of the clusters with multiple CPUs per node, faster CPUs and better connection between the nodes to enable them to more efficiently work in parallel has been key to accomplishing the simulations in this paper,” says Zeng.

Zeng adds that he also greatly appreciates the responsive and supportive RCAC staff, who responded promptly whenever he encountered any problems along the way.

Greeley and Zeng have a long history of collaborating with RCAC and have previously used other clusters for work that resulted in a Science paper about the development of a new method for evaluating the optimal thickness of 2D catalysts for hydrogen fuel cells.

That work involved performing simulations to predict that the inherent force on the surface of a palladium electrocatalyst could be manipulated for the best possible properties. According to the simulations, an electrocatalyst five layers thick, each layer as thin as an atom, would be enough to optimize performance, a finding that would cut down on electrode costs and make fuel cell vehicles more affordable.

To learn more about Bell and other RCAC resources, contact rcac-help@purdue.edu and visit the RCAC website.